1000lph Reverse Osmosis System Water Filter Purifier Desalination Water Treatment Equipment Water Purification System RO Drinking Water Treatment Plant

Basic Info.

| Model NO. | KYRO-1000 |

| System Recovery Rate | >=60% |

| Warranty | 1 Year |

| System Salt Rejection Rate | >=97% |

| Power Supply | AC380 50Hz 3phase or 220V 50Hz Single Phase |

| Feed Water TDS | <=10000mg/L |

| Sterilizer | UV, Ozone |

| RO Membrane | USA Filmtec Dow or Vontron |

| Type | Reverse Osmosis |

| Transport Package | Wooden Case |

| Specification | CE, SGS, ISO Certification |

| Trademark | Kaiyuan |

| Origin | Guangzhou, China |

| HS Code | 8421219990 |

| Production Capacity | 200 Sets/Mouth |

Product Description

1000lph Reverse Osmosis System Water Treatment Equipment Water Purification System RO Drinking Water Treatment PlantTips: 1gallon=3.785 liter 1m3=1000 liter= 1ton

The reverse osmosis(RO) water treatment plant is an equipment to purify water with the action of pressure difference of semi permeable membrane. RO membranes can effectively remove majority of organics, harmful substances, bacteria, particulates etc in the raw water. RO system is widely used in water treatment, purification for tap water, well water, underground water, borehole salty water, brackish water and seawater, pure water and ultra-pure water production, power stations, electronic industries, cosmetics production, medicine(pharmaceuticals) manufactories, and medical treatment(such as hemodialysis). It is a key equipment for pure water plant and ultrapure water equipment.

Different Water TDS(Total Dissolved Solids) compare and usage

| Raw water/Application | Bottled water,Bag water | City tap water | Brackish water | Seawater |

| TDS Range | 2-10ppm | 100-1000ppm | 2000-20000ppm | 20000-40000ppm |

| Direct Drinking | Yes | Yes/No | No | No |

| Cooking, humanconsumption, washing | Yes | Yes | No | No |

| Irrigation, Industry,Animal Drinking | Yes | Yes | No | No |

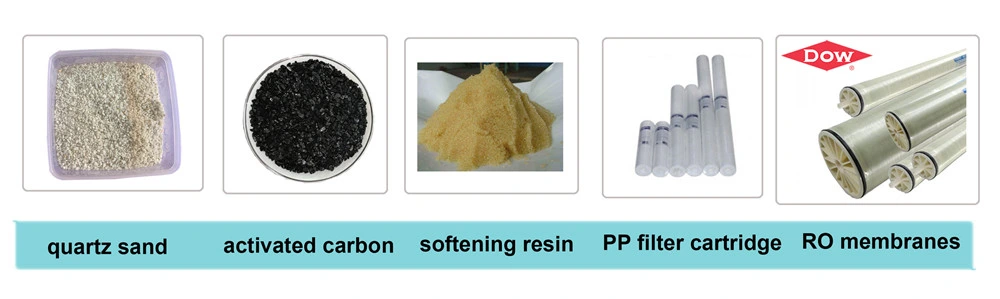

The process of RO water treatment systemRaw water pump→ mechanical filter(quartz sand filter)→ activated carbon filter→sodium-ion exchanger(water softener)→ security filter→ high pressure pump →Reverse osmosis→ Ozone sterilizer (UV sterilizer).Main Parameter of the 1000LPH reverse osmosis system

| Model | KYRO-1000 |

| Production capacity | 1000 L/Hr |

| Power | 2.5KW |

| Power supply | AC 380V 50Hz 3phase or 220V 50hz single phase |

| Reverse osmosis (RO)membrane | LCLE-4040 4pcs USA DOW |

| Membrane housing | Fiber glass reinforced plastic (FRP), 4040 4pcs |

| Raw water pump | Nanfang |

| Quartz sand filter, activated Carbon filter | 350 × 1450 FRP 2pcs |

| Water softener | 300 × 1400 FRP 1pc |

| Security filter | 20 "× 5μm , 5pcs |

| High pressure pump | Nanfang |

| Quartz sand | 150 kg |

| Activated carbon | 50 kg |

| Resin | 75L |

| Size (mm) | main machine: 2310X630X1840 |

Replacement time of consumable parts

There are several kinds of consumables you need to replace regularly.a. Quartz sand: replaced about every 15-18 months. 50kg/bagb. Activated carbon: replaced about every 15-18 months. 25kg/bagc. Resin: replaced about every 15-18 months. 25L/bagd. PP Filter cartridge: replaced about every 1 monthe. Ro membrane: replaced about every 2 yearWe suggest customers buy 1- 2 years of PP filter cartridges together with machine. Because these PP filter cartridges need to be replaced every month. The replacement time also depends on the water source quality.

Each part function of the drinking water purification system

| S/N. | Commodity name | Application | Remark |

| 1 | Raw water tank | Store water, buffering pressure, overcome instability of supplying water by pipe, ensure to supply water stably and continuously for whole system | Customer provide for themselves, because big size will result in expensive freight. |

| 2 | Raw water pump or called booster pump (feed water pump) | Provide needed pressure for every pretreatment filter | We can provide CNP pumps |

| 3 | Mechanical filter or called quartz sand filter or sand filter | We use fiber glass or stainless steel vessel as housing, fill quarts sand, it can filter big particles impurities, suspended substances, colloids etc. | We use China brand or WAVE CYBER brand |

| 4 | Activated carbon filter | We use fiber glass or stainless steel vessel as housing, fill activated carbon, remove color, odor, residual chlorine and organics substances. | We use China brand or WAVE CYBER brand |

| 5 | Water softener, demineralizer, or called Na+ exchanger | Adopt cation resin to soften water, cation resin will absorb Ca2+, Mg2+(main elements for composing scale), reduce hardness of raw water, System can make resin intelligently regenerate, recycling | We use China brand or WAVE CYBER brand |

| 6 | Antiscalant dosing system or PH regulating system | Dosing antiscalant into feed water, prevent the ro membranes from blocking, prolong the lifetime of RO membranes. Regulating PH to suitable range. | Italy SEKO dosing pump or German Prominent |

| 7 | Security filter or pp filter, or called PP sediment filter | prevent large particles, bacteria, viruses into RO membrane, accuracy is 5µm | Stainless steel housing or PVC housing |

| 8 | High pressure pump | Provide needed working pressure for RO system, ensure production capacity of pure water. | CNP pump |

| 9 | RO(reverse osmosis) system | Can remove particles, colloids, organic impurities, heavy metal ions, bacteria, virus, heat source etc. harmful substances and 99% dissolved salts. | RO membranes USA Filmtec Dow |

| 10 | CIP cleaning system | Cleaning RO membranes with chemicals | CNP pumps |

| 11 | Sterilizing device | UV sterilizer or ozone generator | BNP ozone machine, USA Hanovia UV bulb |

Features and Advantages

1.System can produce water continuously and high degree automation.

2.No need chemical to regenerate, easy operation and maintenance.

3.Core components of ro system are imported USA DOW membranes.

4.Automatic switch on when low water level, and switch off when high water level

5.System flushes RO membranes automatically, reducing membranes polluted speed.

6.Water shortage protection for multi-stage pump

7.Product water conductivity meter can monitor water quality online continuously.

8.Low operation cost and long life span

9. There's RO controller, make whole RO system operating automatically.

10.Easily control and Maintained.

11. Auto flush and backwash the prefilters

12. Integrating water flow indicator, conductivity indicator, pressure indicator, control panel

1)Electronic industry, semiconductor industry ultrapure water treatment

2)Chemical industry, pharmaceutical industry pure water treatment

3)Food, beverage, drinking water, bottled drinking water, sachet/pouch packing pure drinking water treatment

4)Electroplating and leather industry waste water treatment

5)Brackish water desalination, sea water desalination, metallurgy and light industry pure water treatment

6)Cosmetic products, car battery, liquid fertilizer production pure water treatment

7)Edible cube ice, tube ice etc.

8)School, hotel, hospital, laboratory, surface treatment, hydraulic test, industrial boiler, power station boiler, high pressure boiler water treatment

Production capacity we can provide as below

| Model | Flow rate (L/h) | Power(KW) | Water use efficiency | RO membrane | Dimension L X W X H(mm) |

| KYRO-250 | 250 | 1.5 | ≥ 15% | 4040 | 1550X620X1670 |

KYRO-500 | 500 | 1.5 | ≥ 50% | 4040 | 1650X630X1800 |

KYRO-750 | 750 | 2.5 | ≥ 50% | 4040 | 1870X 630 X 1850 |

KYRO-1000 | 1000 | 2.5 | ≥ 50% | 4040 | 1870X 650 X 1850 |

KYRO-2000 | 2000 | 3.5 | ≥ 50% | 4040 | 2440X650X1750 (host machine) |

KYRO-3000 | 3000 | 4 | ≥ 50% | 4040 | 2440X620X1850 (host machine) |

KYRO-5000 | 5000 | 7.5 | ≥ 50% | 8040 | 2000X900X1800 (host machine) |

KYRO-6000 | 6000 | 9.5 | ≥ 60% | 8040 | 3000X900X1800 (host machine) |

KYRO-8000 | 8000 | 13.5 | ≥ 60% | 8040 | 3000×900×1800 (host machine) |

KYRO-9000 | 9000 | 14 | ≥ 60% | 8040 | 4000X900X1800 (host machine) |

KYRO-10T | 10T/H | 19 | ≥ 60% | 8040 | 3000X900X1800 (host machine) |

KYRO-12T | 12T/H | 19.5 | ≥ 60% | 8040 | 4000X900X1800 (host machine) |

KYRO-15T | 15T/H | 23 | ≥ 60% | 8040 | 4000X900X1950 (host machine) |

KYRO-20T | 20T/H | 28 | ≥ 60% | 8040 | 5000X900X1950 (host machine) |

KYRO-30T | 30T/H | 55 | ≥ 60% | 8040 | 7000X900X1950 (host machine) |

Buying Guides

2. Inform us the production capacity of the reverse osmosis system (500L/h, 1000L/h,3000L/h...) you need, source water(tap water, well water, borehole water etc.) and application of output pure water from the reverse osmosis system.

3. We will make a plan and quotation for the reverse osmosis system immediately as your requirements.

4. Confirm details of the reverse osmosis water treatment plants (specification, consumable parts, power supply, delivery time, payment terms, shipping cost, packing details etc. At the same time, you are also welcome to visit our factory and we talk face-to-face.

5. Sign sales contract or proforma invoice for this reverse osmosis system.

6. Pay 30% deposit for confirming this order

7. We confirm receipt of the deposit and start to produce the RO machine.

8. After finish production for ro machine, we take pictures and send to you.

9. Pay balance and we arrange packing for the RO machine (if it is other payment terms(such as L/C), we can negotiate accordingly.

10. Arrange shipment or send the reverse osmosis system to your appointed warehouse.

11. Send the Bill of loading, commercial invoice, packing list, certificate of origin and insurance policy to customers via DHL or UPS or FedEx etc. for custom clearance.

12. Customers receive the reverse osmosis systems, then install and operate it as our manual book or operation video of the RO machine. our engineers are also available to service overseas.

13. Business finished, all our ro machine quality is guaranteed for 1 year and with free lifetime technique support. Please contact us freely.

About our company:

Guangzhou Kaiyuan Water Treatment Equipment Co.,ltd is located in Guangzhou city,China, has been engaged in water treatment since 2006. We are specialized in manufacturing reverse osmosis drinking water treatment plant, industrial pure water equipments, ultrapure water equipments, underground water treatment plants, brackish water treatment systems, EDI ultrapure water systems, sachet water packing machine and bottled water filling machines etc.

Our products are sold well not only in domestic, but also in Britain, America, Canada, Italy, Spain, France, Netherlands, Lithuania, Germany, Poland, Cyprus, Bahrain, Russia, Ukraine, Mongolia, UAE, Saudi Arabia, Lebanon, Tunisia, Singapore, Australia, Indonesia, Malaysia, Brunei, Philippines, New Zealand, New Caledonia, Kazakhstan, Uzbekistan, Oman, Yemen, Sri Lanka, Bangladesh, India, Vietnam, Nepal, Laos, Myanmar, Thailand, Peru, Chile, Ecuador, Mexico, Ecuador, Haiti, El Salvador, Paraguay, Venezuela, Bolivia, Guatemala, Somalia, Benin, Nigeria, Tanzania, Kenya, Uganda, Cameroon, Libya, Liberia, Algeria, Rwanda, Ghana, South Africa, Zimbabwe, Zambia, Senegal, Sudan, Zambia, Ethiopia, Egypt, Botswana, Morocco, Congo, Cote d'ivoire etc. countries.

Our main products:

Reverse Osmosis (RO) system/ RO drinking water system/ Ultrafiltration (UF) system/ Mineral water plant/ Water softener/ Iron removal plant/ Seawater desalination plant/ Brackish water treatment system/ EDI Ultrapure water equipment/ Ion Exchanger system/ Mixed Bed/Water treatment accessories.

Contact us:Add:Dehui Wanggang Science Park, Industrial 3 Road, Jiahe Wangwang, Baiyun District, Guangzhou, Guangdong Province, China.

Mobile: 0086 15102048719